In this article, the combination of super capacitor and battery is applied to the electric bicycle to form a dual power supply system. The double source connection mode is designed and the super capacitor can be connected to the battery in parallel through the bidirectional DC/DC converter, so that the super capacitor can release more power. The optimal working condition under constant power effectively guarantees the battery from impact and prolongs the service life of the battery.

1. Summary

As a short distance vehicle with energy conservation, environmental protection and convenient travel, electric white driving is welcomed by consumers.At present, the existing problems of E-bike mainly are the service life and frequent replacement of the battery, the long storage and charging time of the battery, the limited charging and discharging times, and the poor contact, etc. Therefore, the battery is the key component affecting the performance and quality of E-bike, and also the key problem restricting the development of E-bike. In recent years, many countries with advanced science and technology are committed to the research and development of new electric bicycle batteries, including high-power nickel cadmium, zinc nickel, nickel hydrogen, lithium polymer and fuel cells. Nickel hydrogen battery is widely used in Japan, Europe and America, and lithium ion/ lithium polymer battery is also widely used.Many research institutes in China are also actively developing new batteries for e-bikes, but about 95% of e-bikes still use traditional lead-acid batteries. However, due to the short life of the lead-acid battery, it needs to be replaced in about one year. Moreover, when the electric bicycle is starting, speeding up, facing headwind and loading, the battery needs to provide dozens of amperes of current to drive the motor in a short period of time, but the lead-acid battery is difficult to achieve, and such a large current will cause impact damage to the battery, which will seriously impact of battery life and mileage. In this article, the super capacitor and the battery are combined for driving the electric bicycle, and the connection mode of dual power supply is designed reasonably. According to the characteristics of the electric bicycle motor drive, the control strategy is designed. The control strategy can effectively improve the performance of the electric bicycle, extend the service life of the battery, and has a great market prospect.

Super capacitor, also known as electrochemical capacitor, is a kind of energy storage device between battery and capacitor. It not only has the characteristics of rapid charge and discharge as capacitor, but also has the energy storage mechanism as electrochemical battery.

Super capacitors have the following characteristics:

① Large capacitance. The capacitance of a single super capacitor is 2000-10000 times larger than that of electrolytic capacitor of the same volume, which can reach thousands of methods or tens of thousands of farads.

② High power density. Super capacitor can provide large instantaneous current. In a short time, the current can reach hundreds to thousands of amperes, and the power density is nearly 100 times that of battery, which can reach 1000W/kg.

③ Charging fast. Charging for a few minutes can reach more than 95% of the rated capacity.

④High energy conversion efficiency and strong charge-discharge acceptance ability. The energy cycle efficiency of high current charging and discharging is more than 90%, and the energy loss is small during charging and discharging.

⑤Long cycle life. Under normal use conditions, the number of cycles can reach more than 100,000 times.

⑥Wideworking temperature range and high reliability. It can work normally, safely and reliably in the temperature range of - 40-65℃.

3. Super capacitors combined with batteries

The super capacitor and battery are combined reasonably to form a dual power supply, which is arranged on the electric bicycle to jointly drive the electric bicycle. When the electric bicycle normally runs on a flat road, it is powered by the battery alone. In the stage of starting, climbing, accelerating and other needs of instantaneous high power, the super capacitor and the battery supply power to the motor at the same time. When the electric bicycle is braking, the motor generates electricity, and the super capacitor stores energy to realize energy recycling. The combination of super capacitor and battery can complement each other and improve the performance of existing battery and prolong its service life. However, the super capacitor has low energy density and large series internal resistance. If the series super capacitor bank is directly connected with the battery bank in parallel, the output current of the super capacitor bank will be too small due to the excessive internal resistance, which will not play the role of shunt protection of the battery. Therefore, a bi-directional DC/DC converter is designed, the super capacitor can be paralleled with the battery through the DC/DC converter, and the output power can be adjusted at will. Therefore, a certain control method must be built during operation, which can start or expand the output current of super capacitor in time when the motor current demand is too large, and limit the output overload current of battery to protect the battery. The control method is determined according to the operation conditions of the electric bicycle, which can be divided into flat driving, starting, speeding up, climbing, overloading, braking, etc.

3.1 Start up,speeding up, climbing and overloading

In those state, the motor needs instantaneous high power, and the super capacitor and the battery should output power together to drive the motor. As the super capacitor has the characteristics of short-time high current discharge compared with the battery, the super capacitor can better meet this requirement. At this time, the super capacitor can bear most of the load. Therefore, in this stage, the super capacitor needs to be the main energy source to offer the peak power, while the battery only serves as the auxiliary energy source. After the peak power releasing, the super capacitor exits and the load is borne by the battery.

3.2 Running under uniform speed on flat road

When the electric bicycle is running under uniform speed on flat road, the power demand is not high. The output power of the battery can completely meet the requirements of the motor power. The energy for motor is completely provided by the battery alone, and the super capacitor does not need to release power.

3.3 Braking status

The motor of electrical bicycle is in the power generation state when braking, and some kinetic energy is converted into electric energy, which can be sent back to the super capacitor through the bidirectional DC/DC converter inversion. Under this state, the circuit between the battery and the motor is cut off, and the battery does not absorb the feedback electric energy, so as to avoid the damage caused by the regeneration current to the battery.

Using the super capacitor as the energy storage container of regenerative braking feedback energy can not only absorb the instantaneous large current, but also effectively improve the energy recovery rate.

The energy management goal of dual power driven electric bicycle is to adopt reasonable control method to realize the complementary advantages of the two energy storage containers, to ensure the dynamic requirements of the electric bicycle, and to make the battery work in the best working state of low current discharge at all times, and, realized better use of super capacitor. Feed back the electric energy generated by regenerative power generation braking mode to super capacitor, is not only improves the recovery rate of energy, but also protects the battery from impact and prolongs its service life.

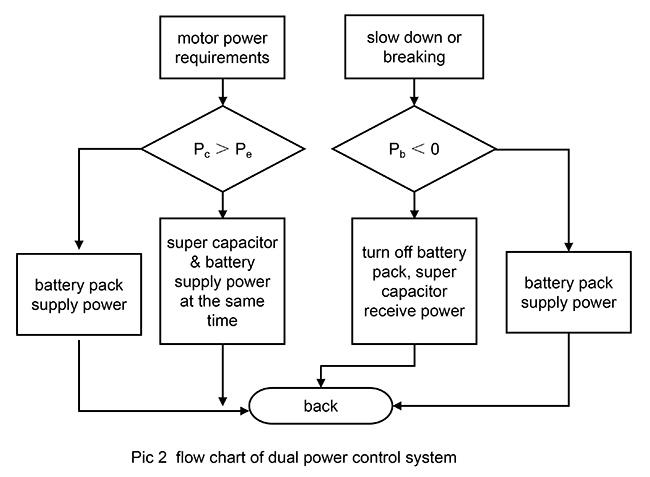

The working state of the electric bicycle can be distinguished according to the driving power of the detecting motor. When the driving power is positive and large than the rated power of the dry battery, and △P/ at > O, it can be judged that the electric bicycle is starting, climbing or overloading. At this time, the duty cycle of the battery control circuit PWM should be reduced to reduce the output of the battery, the duty cycle of the super capacitor control circuit PWM should be increased to increase the output of the super capacitor at the same time. When the power is positive and less than the rated power of the battery, it can be judged that the electric vehicle is in the flat driving state: when the power is negative and △P/△T < 0, the electric vehicle is braking, the super capacitor will be charged, and the receiving feedback energy.

4. Design of control circuit

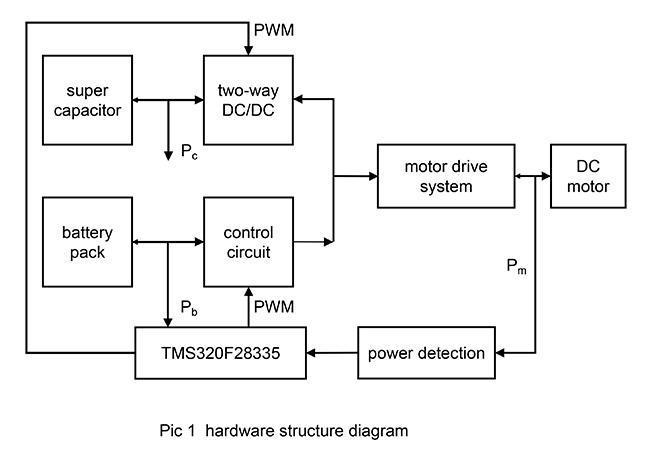

In this article, TM $320f28335 is used as the core controller to design the dual power control circuit system of electric bicycle to realize the control method. In this scheme, the voltage of the super capacitor and the battery is not equal, the voltage of the battery is 48V, the voltage of the super capacitor is 36V, and the battery is connected in parallel through the bidirectional DC/DC inverter. The hardware circuit diagram is shown in Figure 1: the power detection circuit in the figure is responsible for detecting the power PC, Pb at the output side of the dual power supply and the driving power P of the motor. When it is in the state of starting, climbing and overload, DSP outputs boost PWM waveform to bidirectional DC/DC converter, the converter works in boost mode, and super capacitor releases the stored energy. Meanwhile, DSP controls PWM duty cycle of battery control circuit to ensure the output power of battery is within the rated power. When the motor is in the state of deceleration or braking, DSP outputs Buck PWM waveform to the bidirectional DC/DC converter, cuts off the power supply circuit of the battery at the same time, the bidirectional DC/DC converter works in the buck mode, and feeds back the regenerative braking energy to the super capacitor for storage.

Max4211 chip can be used for power detection. The chip has low cost and low power consumption. It can form a high-end DC power /DC current measurement system. The system uses a precision current detection amplifier to detect the current, and then uses an on-chip multiplier to calculate the power. The connection of the system does not affect the grounding path of the tested system, especially suitable for detecting the power and electricity of the battery power supply system Flow. The measurement error is less than 1.5%, the measurement range is 4-28v, the power supply voltage range is 2.7-5.5v, and the working current is 670μa. The flow chart of control method is shown in Figure 2:

This design scheme has been simulated by matlam, and the controller has been made in the laboratory and applied to the control test of electric bicycle. The super capacitor with rated voltage of 12V, capacitor capacity of 1.2F, three groups of capacitors in series of 36V and four 12V batteries in series of 48V are used. The test proves the effectiveness of the control method. In this design, the super capacitor is connected to the battery in parallel through bidirectional DC/DC. The terminal voltage of the super capacitor is not equal to the battery voltage, so the working voltage range is wider and the super capacitor can release more energy.

5. Conclusion

In this article, a dual power supply system composed of super capacitors and batteries is proposed, which is applied to the power supply of electric bicycle. The super capacitor can release more electric energy through the parallel connection of the bi-directional DC/DC converter and the battery. The operation condition of the electric bicycle is discussed, and the control method of the super capacitor and the battery is determined to make the battery in best working condition on the rated power. The battery is effectively guaranteed from impact, and the service life of the battery is effectively extended. The feasibility and effectiveness of the design are proved by experiments. With the continuous development of super capacitors and the decrease of price, the application of combined power supply in electric bicycle will have a better development prospect.

Source:Magazine of science and Practice Translated by: Shanghai Green Tech Co.,Ltd.